Prototyping tooling for molding is ideal when the customer requires between 100–2,000 units of their injection molded parts; more than this and production-level steel tooling may be preferred.

Advantages of rapid tooling include fast turnarounds and the ability to carry out prototyping and testing of injection molded parts that might otherwise take months to produce. Rapid tooling is also significantly cheaper than mass production tooling.

Although rapid tooling and rapid injection molding is more expensive than 3D printing, it provides plastic parts much nearer to production quality that can therefore be used for functional testing.

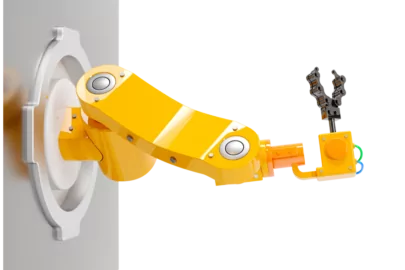

- Plastic Injection Mold

- Die Casting Mold

- Extrusion Mold

Services

Services