What is Die Casting Aluminum Alloy?

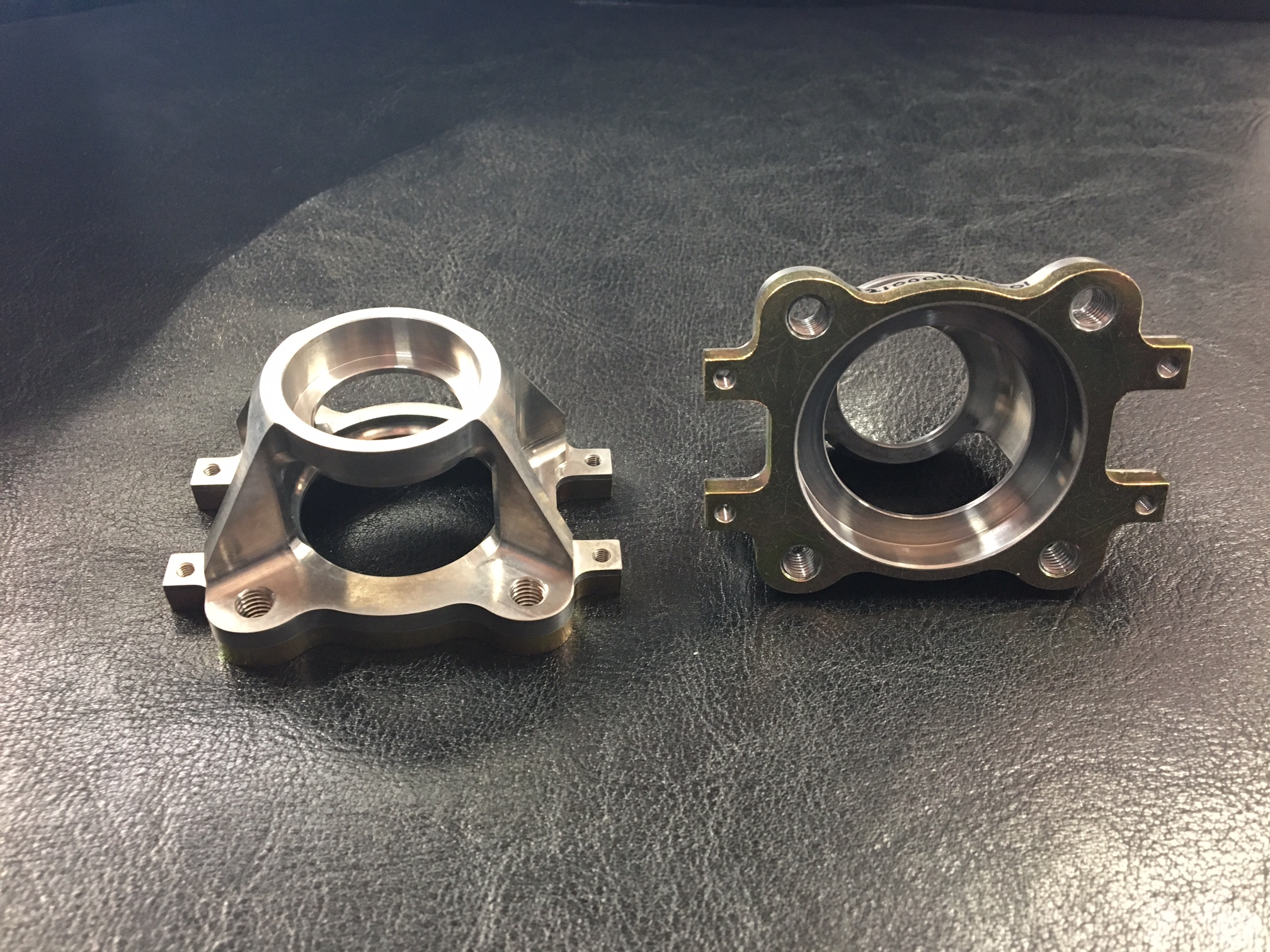

Aluminum die casting is a metal casting process through which forcing molten aluminum alloy under high pressure into a mould cavity. The basic operation of aluminium die casting is to fill a mold with liquid metal and press it into the designed geometry. Everything begins with the mold cavity, which is created using two steel dies that have been machined into shape. Aluminum alloy die casting is precision and reliable process that allows the metal to be cast and molded into the desired shapes in a safe way, which is widely applied in metal forming as the choice of most industrial projects requires metal components.

Aluminum has been widely applied in many fields including electronic enterprises, auto fittings industries and lighting industries due to the advantages of low density, high performance and corrosion resistance.

Die casting process is the most popular methods in mass production of aluminum die castings. There are much automated die casting equipment in Kingcasting to provide aluminum die casting service for many customers, including vacuum aluminum die casting, hot chamber die casting and cold-chamber die casting. Vacuum die cast process reduces the wear of molds by extracting the air in chamber before injecting metal liquid. The metal liquid can fill the molds rapidly through combination of decreasing the back pressure and increasing injection rate.

Services

Services