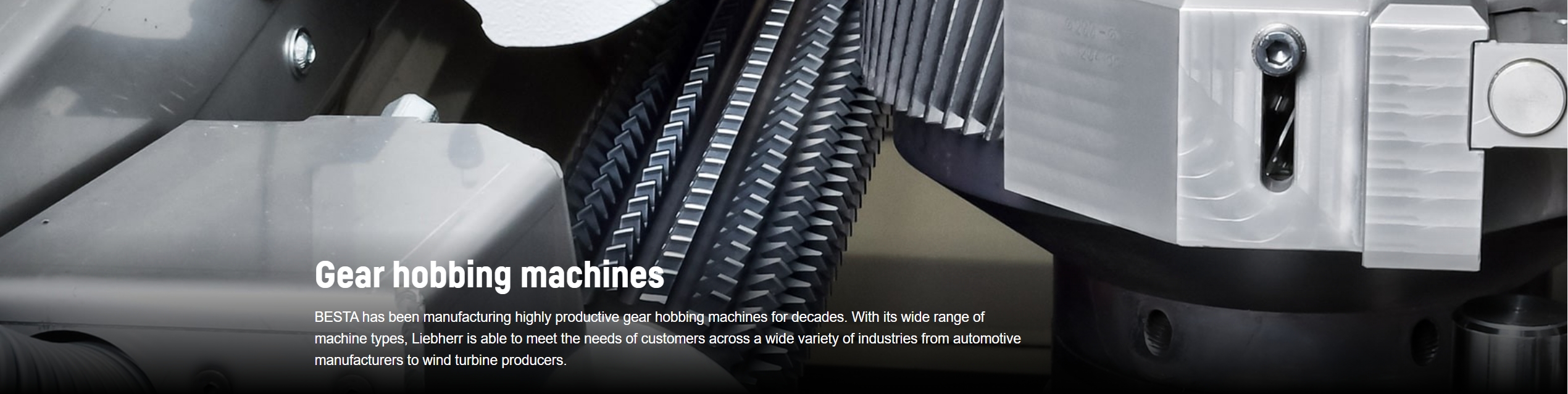

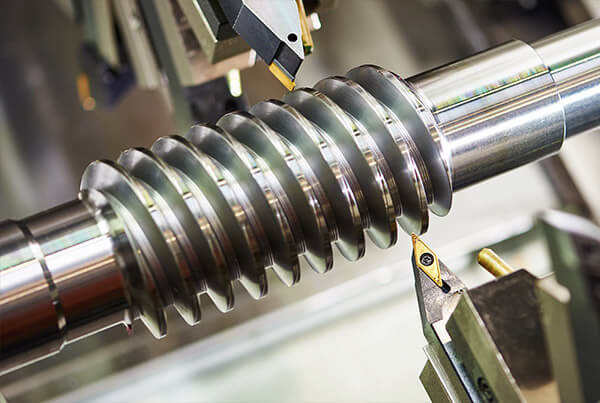

Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob” (hence the term gear hobbing) depicted in the gear hobbing machine interface below. The hob can be single-threaded, depending on how many teeth per revolution should be generated.

Spur gears are most often fabricated with this method, although a variety of other gears — like cycloid gears, helical gears, worm gears, ratchets and sprockets — are all made by hobbing. A well-designed hob is critical, especially when cutting a complex geometry, and this process typically does not work for internal gears. Similar to gear shaping, hobbing has setup advantages, but only for exterior cuts since the hob is cutting the outside of the gear blanks.

Services

Services