Services

Services

Services

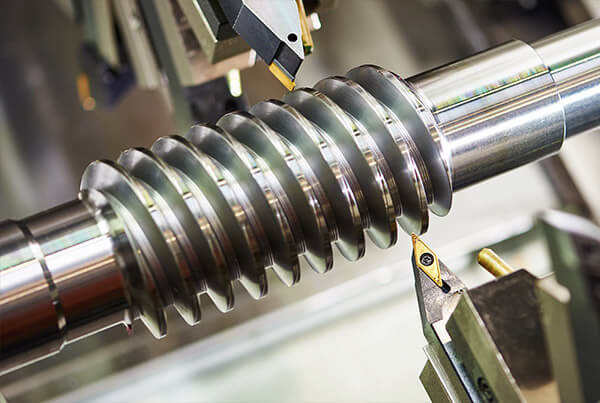

- CNC Machining

- Extrusion Profile

- Wax Casting

- Sand Casting

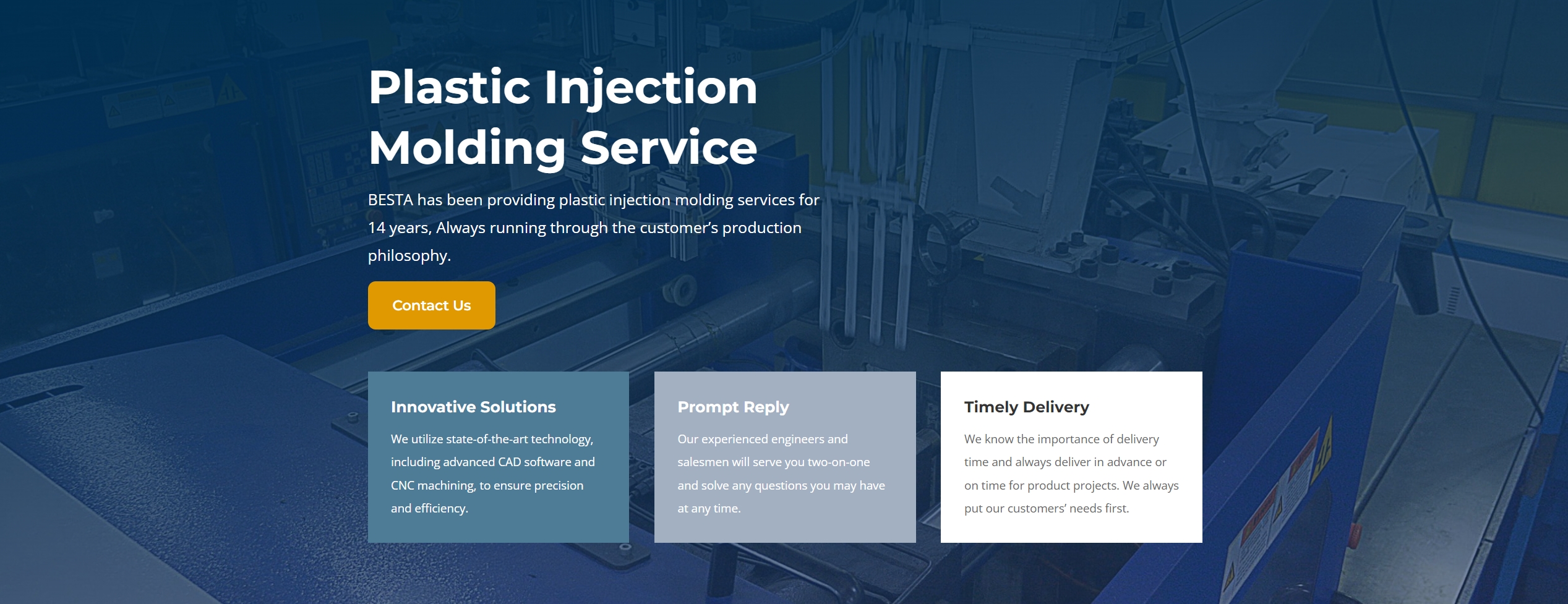

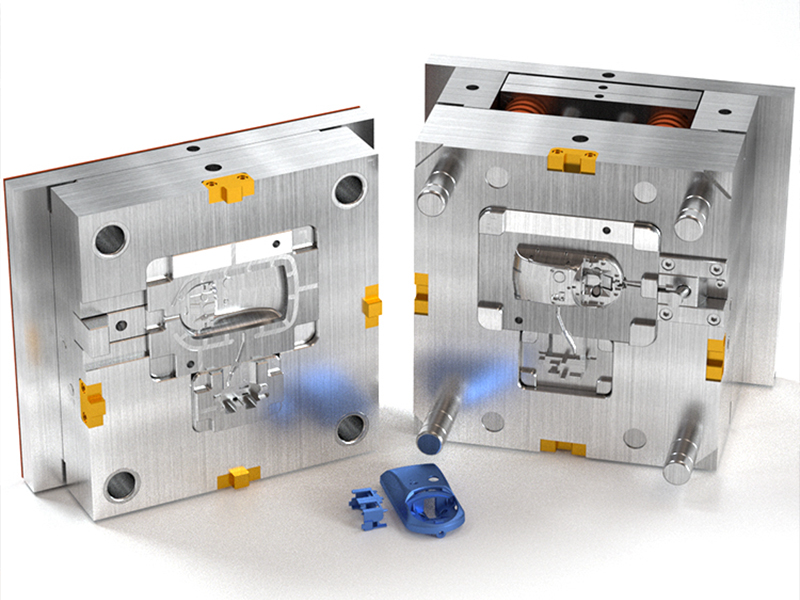

- Injection Molding

- Gear Hobbing

- Die Casting Aluminum Alloy

- Sheet Metal

Related Links

Related Links

Related Links

Die Casting Aluminum Alloy

Die Casting Aluminum Alloy ServicesWe are focusing on:

- Industries

- Resources

- About Us

- Contact