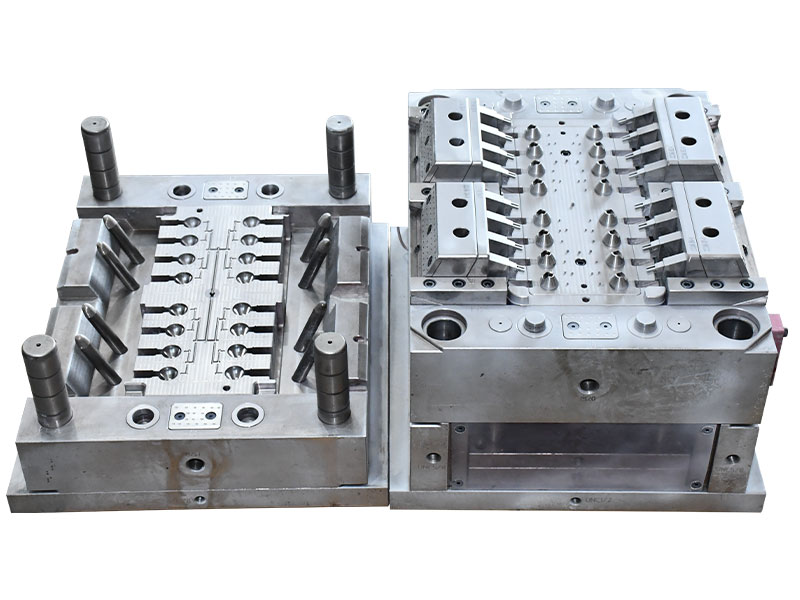

What is Injection Molding?

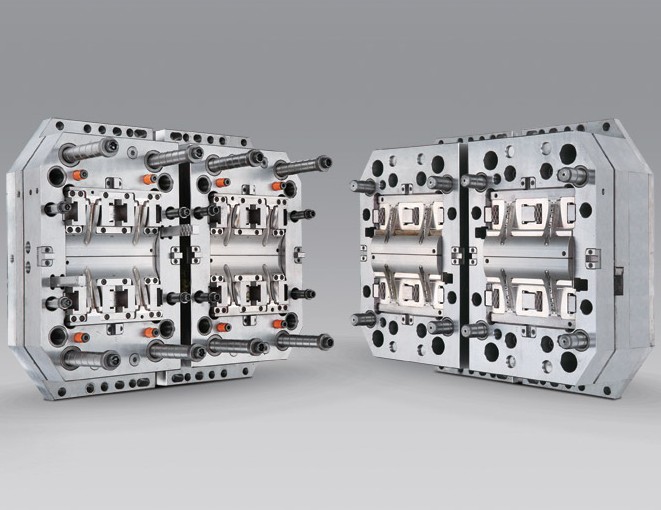

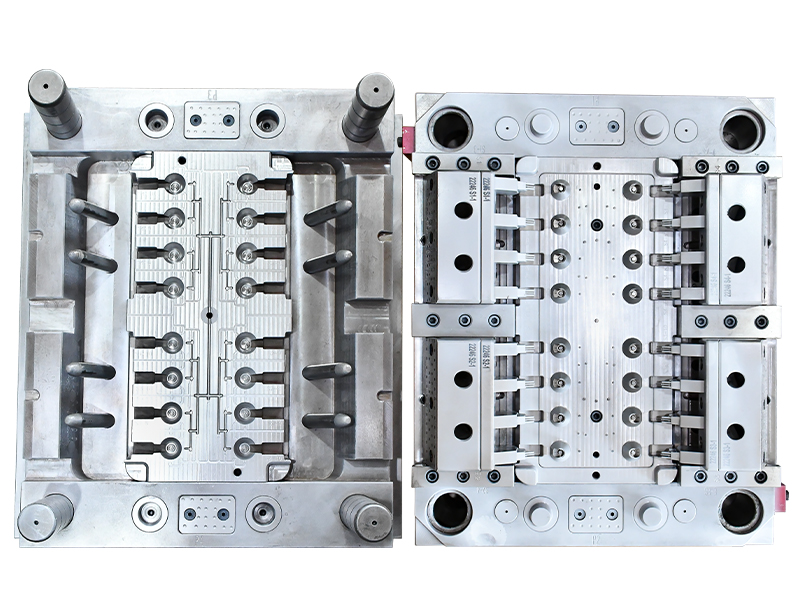

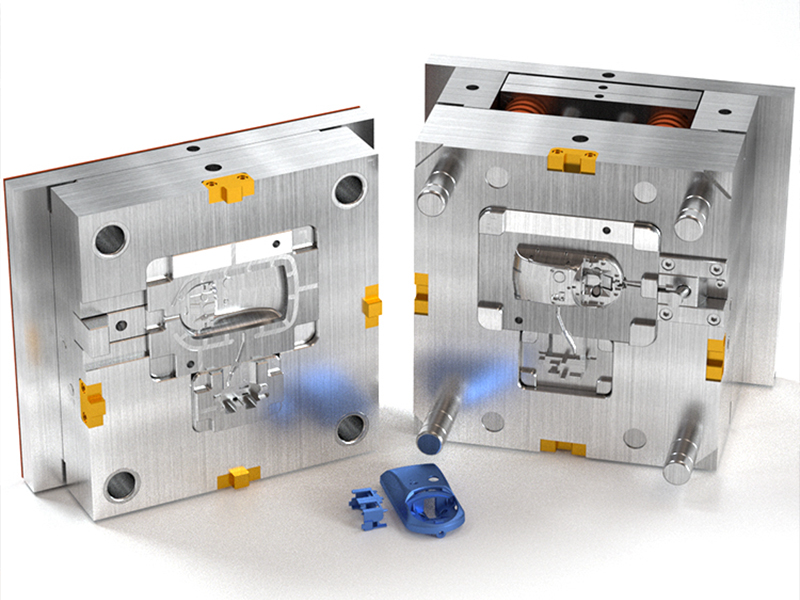

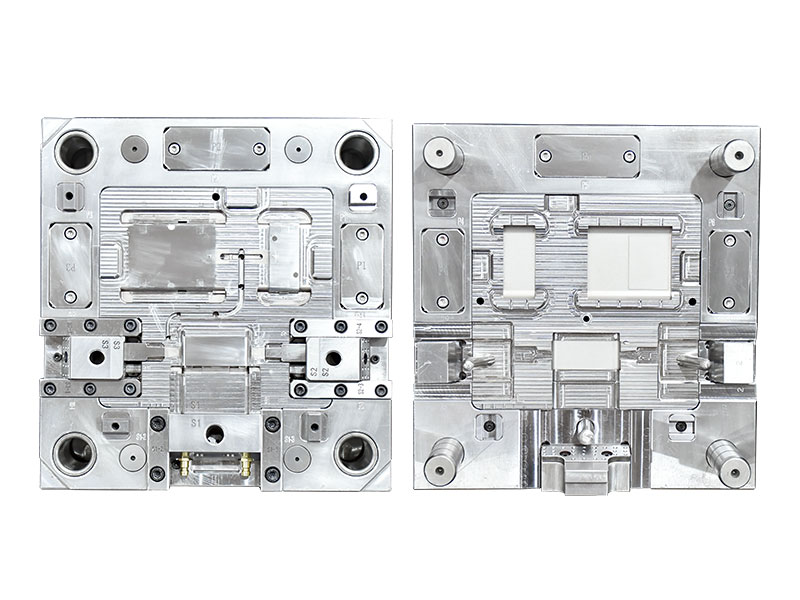

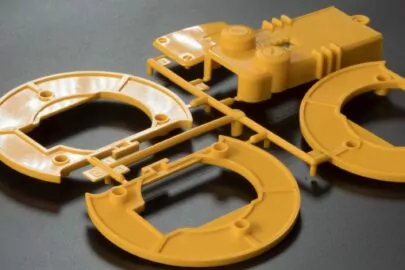

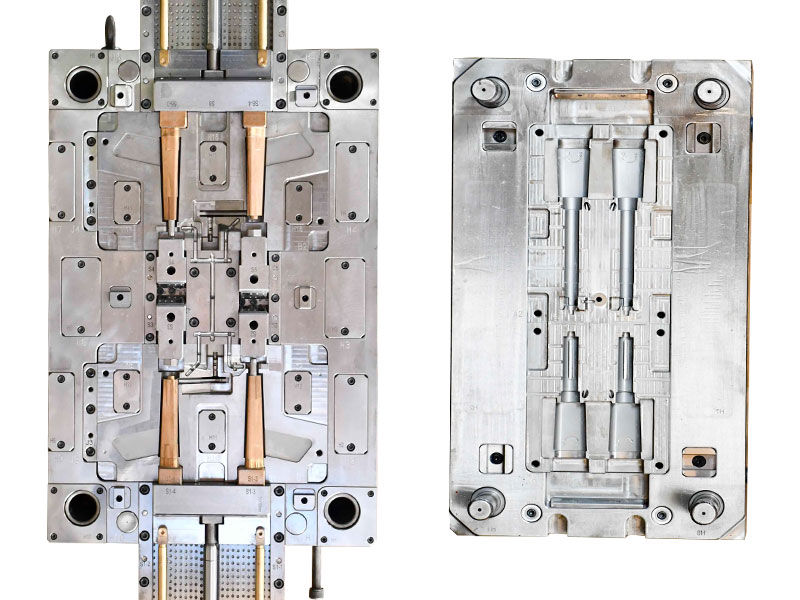

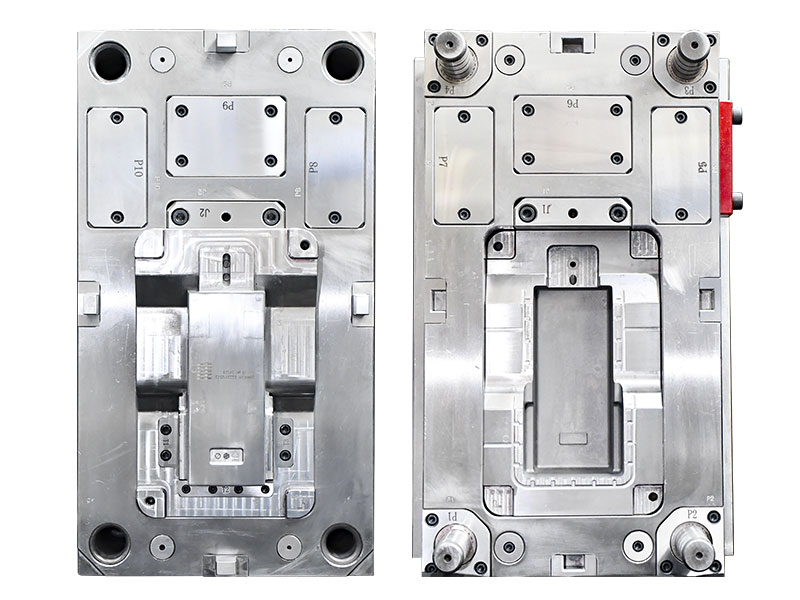

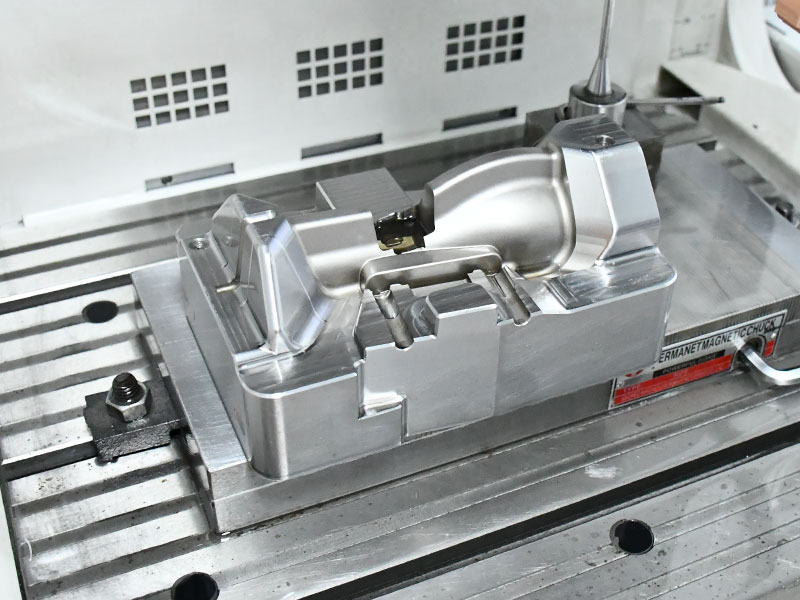

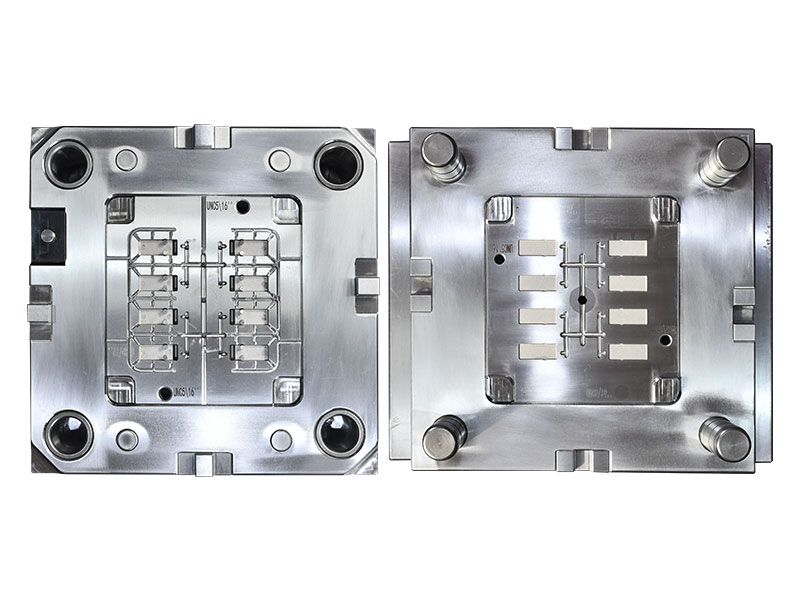

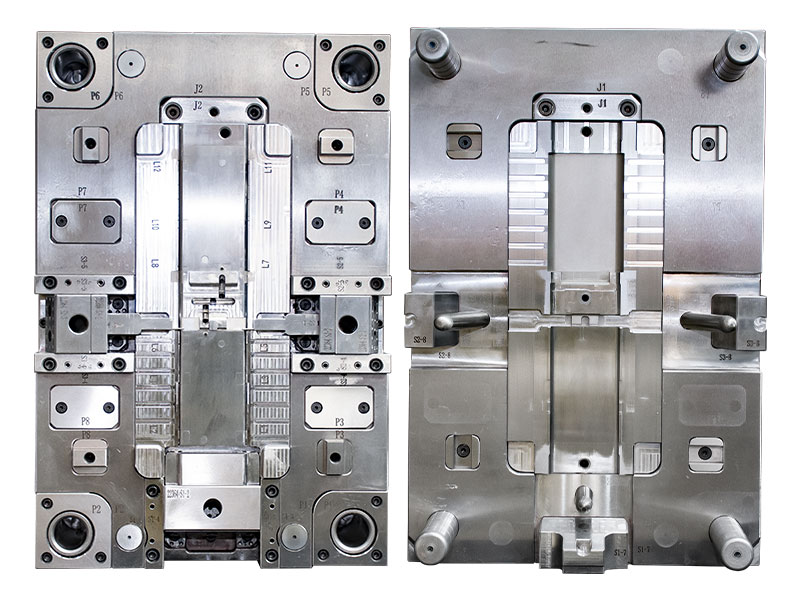

Injection molding is the process of injecting molten plastic into a mold cavity, rapidly cooling it, then ejecting the solidified plastic part. It is the most widely used manufacturing process for plastic parts and the most affordable route to mass production. Once the metal mold or tooling has been made, hundreds, thousands, or millions of plastic duplicate parts can be made in a short timeframe, with the effective cost-per-part reducing with each additional molding as the cost of the mold is amortized. Injection molding is compatible with a very wide range of materials — including thermoplastics, thermosets, and even metals — which can be easily mixed with color pigments and other additives to tweak the function and appearance of the moldings. Furthermore, the injection molding process offers excellent consistency between units, as the tooling remains constant throughout.

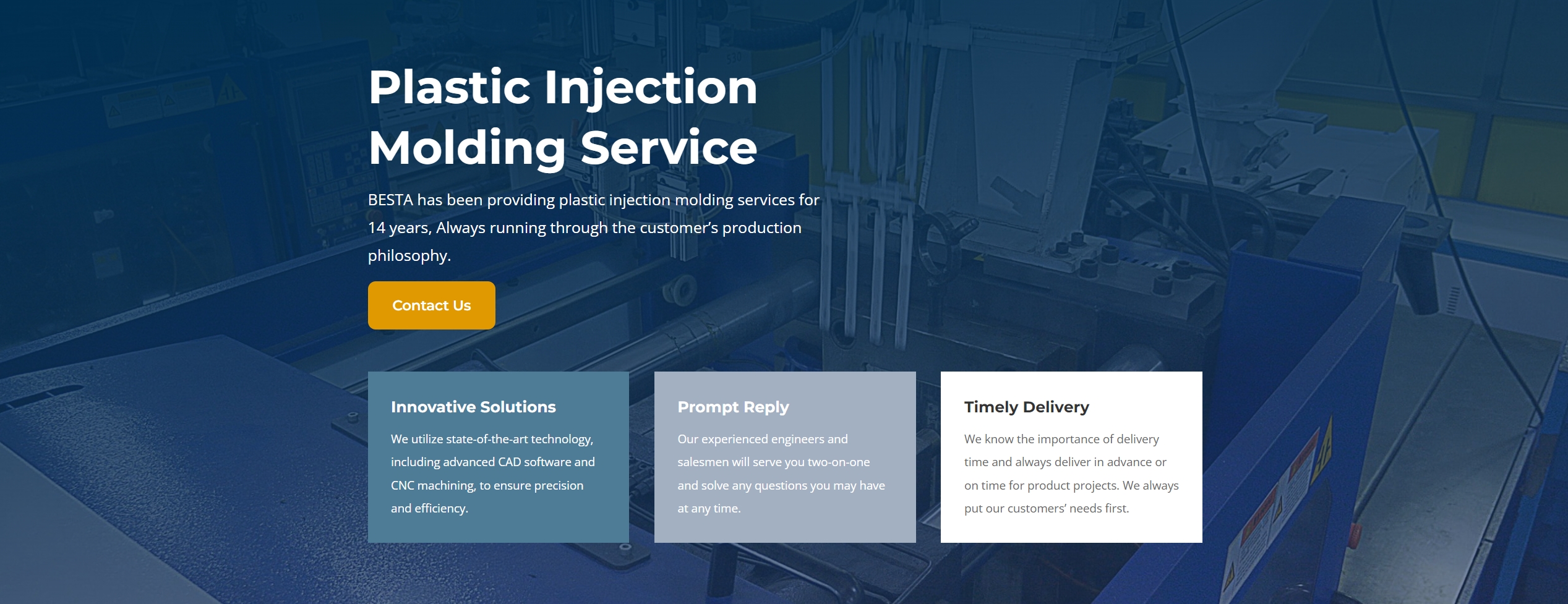

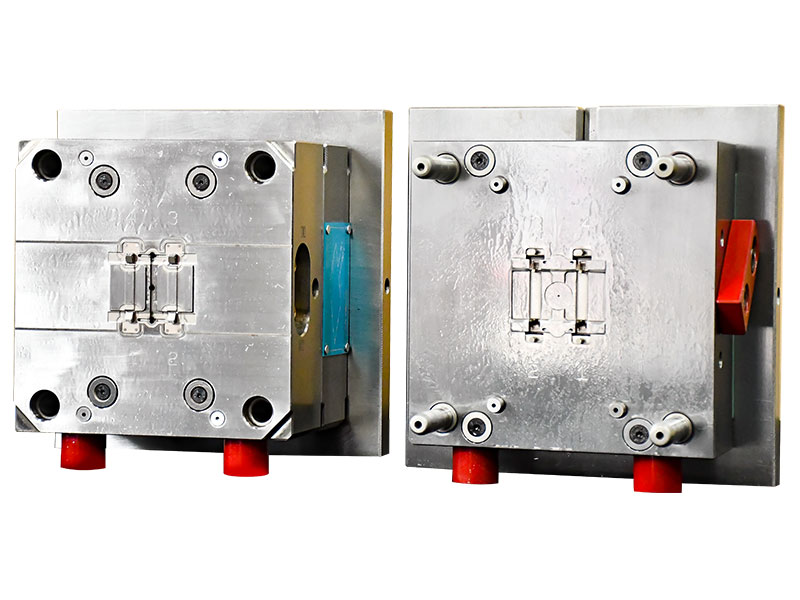

At BESTA, we offer a range of injection molding services, from affordable low-volume prototyping to part production, using thermoplastics, thermosets, or metals. Our team of experienced molding specialists can guide you to the right solution, whether you need rapid aluminum tooling for a fast prototype or a more durable solution for larger production runs. Unlike many molding companies, we do not specify a minimum order quantity.

Services

Services