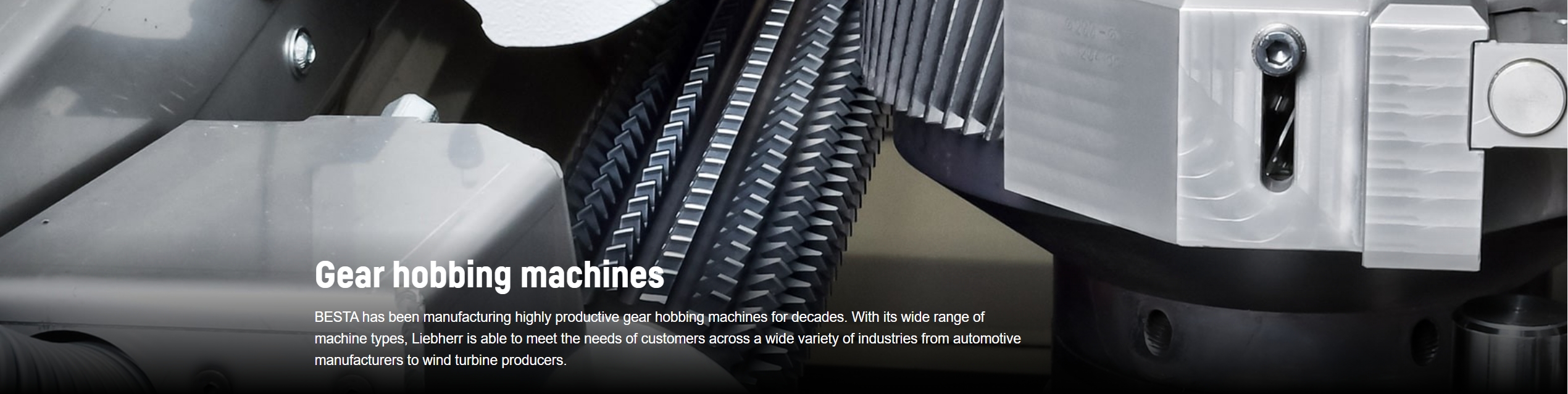

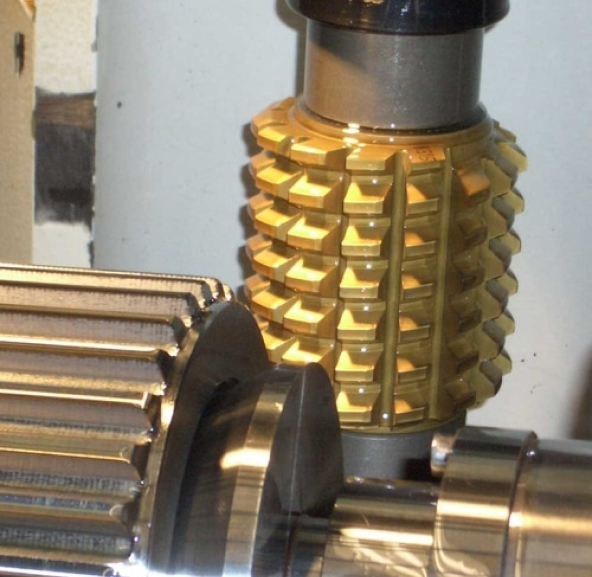

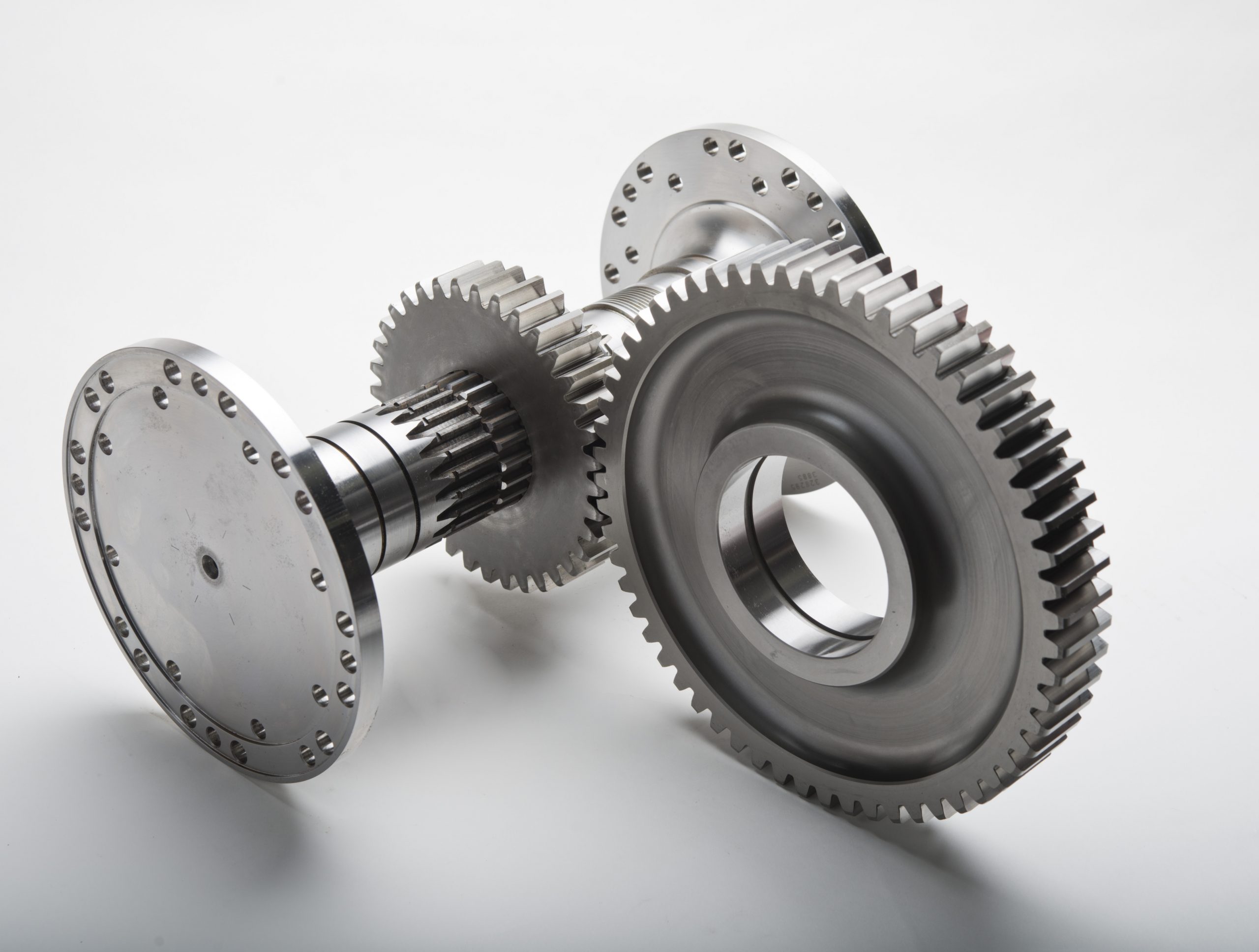

Hobbing is a machining process for cutting gear features on both metal and non-metal parts. The gear teeth (or splines) are progressively cut into a cylindrical piece of material by a series of cuts made by a cutting tool called a hob. Hobbing allows you to achieve various gear shapes and sizes such as spur gears, worm gears and bevel gears. Although gear hobbing can be used for prototyping small quantities, this process is best suited for higher volume production.

Our manufacturing partners have various hobbing tools in stock which allow for quick turnaround times. If a custom gear profile is desired that is not part of our standard hobbing tool library, customers can order custom hobbing tools to be built. If you want to create internal gear features, we offer Electrical Discharge Machining (wire and sinker), as internal gear features cannot be achieved with hobbing.

Services

Services