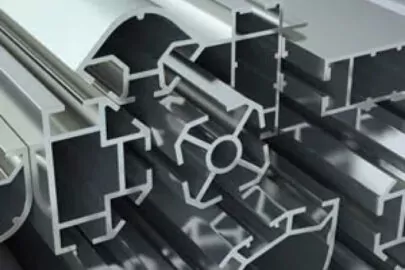

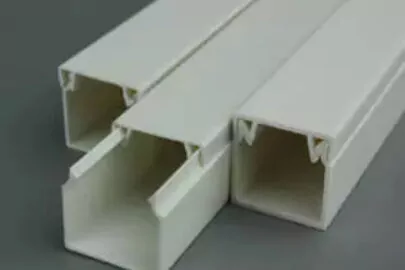

If you are looking for an extrusion profile cut in a certain length and the volume you require is high, you should definitely go with an extrusion company directly. There are lots of extrusion companies dealing with high-volume production. Though, these companies are not willing to handle low-volume aluminum & plastic extrusion projects, unless you are one of their VIP customers. so it is very difficult get prototype aluminum extrusions & prototype plastic extrusions. At BESTA, we have solid partners for short run custom aluminum extrusions & short run plastic extrusion services. They take good care of our projects, both in quality and lead times. We also routinely do quality control on your project before shipment.

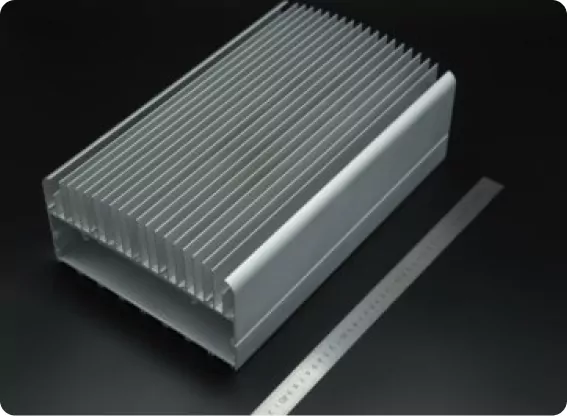

Compared with traditional extrusion companies, we have a large amount of CNC machines, so we can do precision post-machining in house.

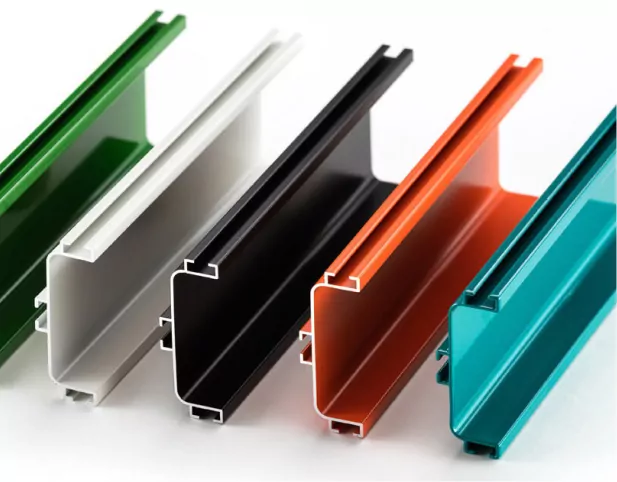

Customization

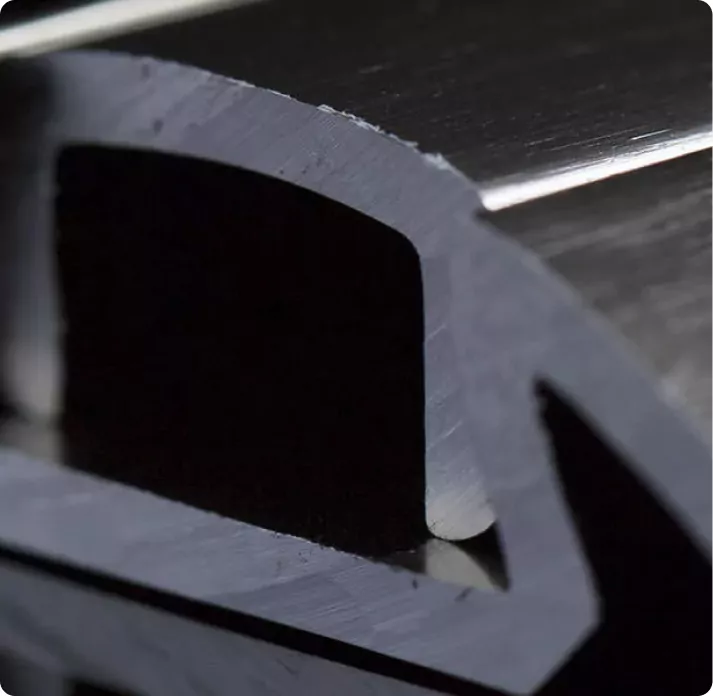

We offer custom aluminum extrusion profiles, and we can combine extrusion with other manufacturing methods such as CNC milling, turning, and bending to make the final parts.

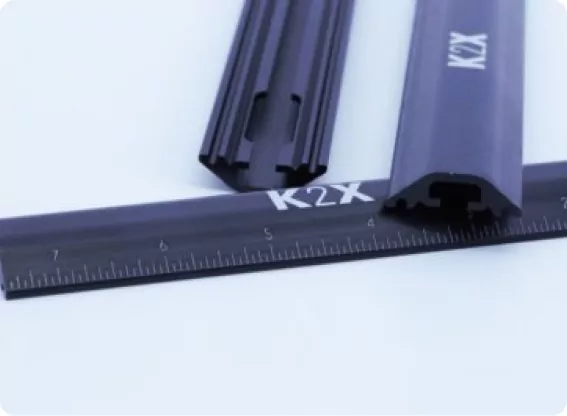

Low Volume

Most extrusion companies set very high MOQs. BESTA doesn’t, so we are the best choice for lower volumes. One-off prototype extrusions or a few hundred units? No problem.

Fast Delivery

If you don’t want to wait 30+ days to get your extrusion mold and profiles manufactured, come to us! We can finish everything in half the industry-standard time or even less.

Services

Services