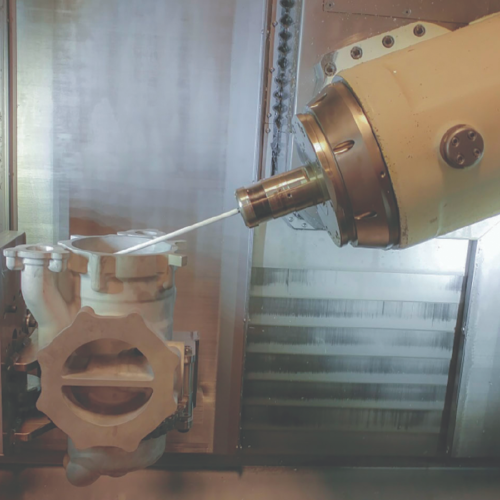

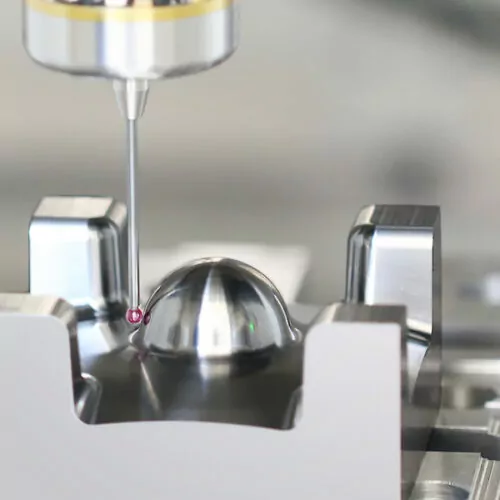

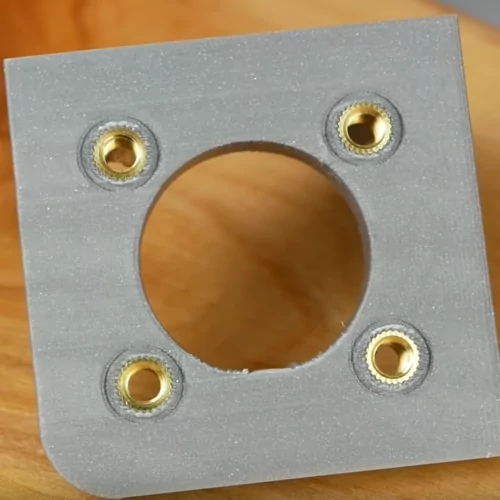

When designers, engineers and businesses take product development into consideration, many of them see prototyping and mass production as the primary goal posts. But there are times when low-volume manufacturing is the optimal choice for those who need modest quantities of finished parts, ranging anywhere from a few hundred to hundreds of thousands. By using a professional prototyping and manufacturing service like BESTA, our customers gain the ability to acquire the exact amount of parts they desire, no matter what the final count might be.

At BESTA, we will be there to help you along every step of the way, from the initial product design review and quotation to quality inspection of your newly manufactured parts. In addition to specialising in prototyping and mass production, we are also specialist when it comes to low-volume manufacturing. Contact our expert team today to get a free project review and initial quotation. If you need a prototype to verify your design first,

please review our rapid prototyping services.

100 to 100,000+

In order to decide whether a low-volume manufacturing service is right for your production needs, it’s important to first understand exactly what low-volume manufacturing is. At the surface, the term is relatively self-explanatory. Low-volume manufacturing is a specialised service that offers mass-production quality parts in a small volume, generally limited to 100,000 parts or fewer – depending on the manufacturing technique used.

Services

Services