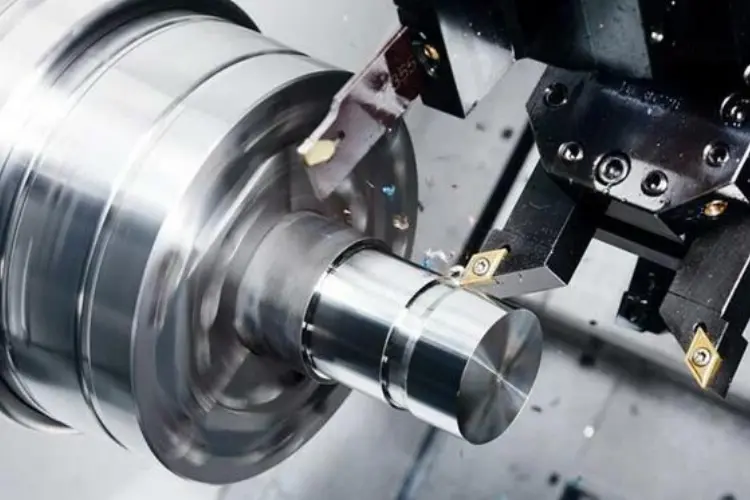

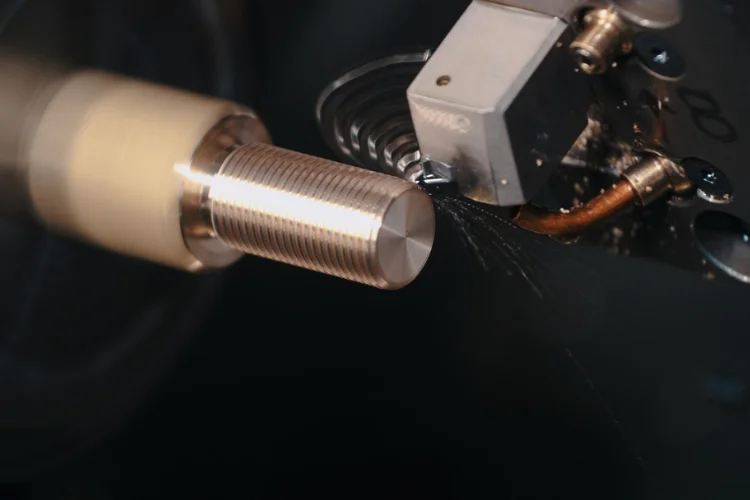

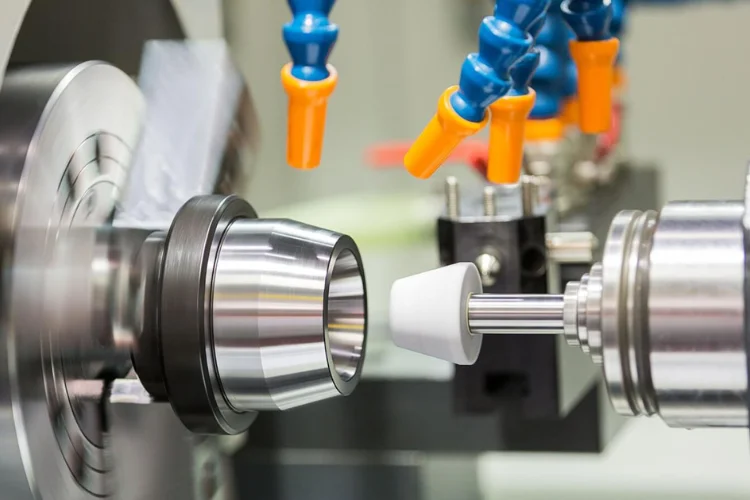

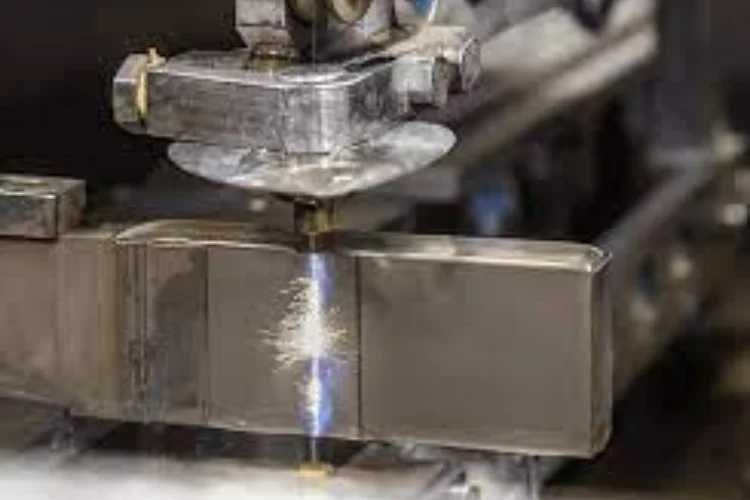

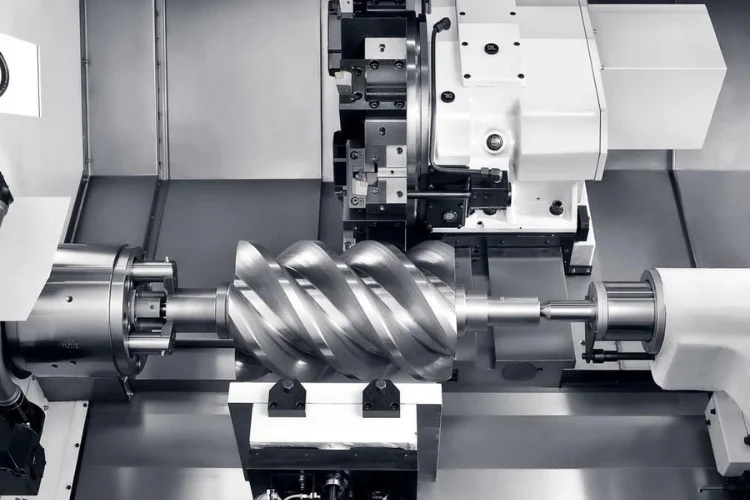

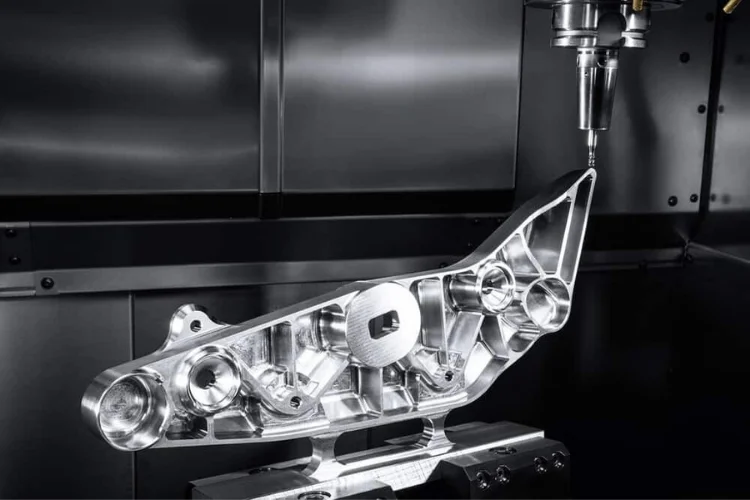

CNC, or computer numerical control machining, is a widely used manufacturing process that uses automated, high-speed cutting tools to remove material from a metal or plastic workpiece until the desired geometry is achieved. Standard CNC machines include 3-axis, 4-axis, and 5-axis milling machines, lathes, and routers. Machines may vary in how CNC parts are cut—the workpiece may remain in place while the tool moves, the tool may remain in place while the workpiece is rotated and moved, or both the cutting tool and workpiece may move together

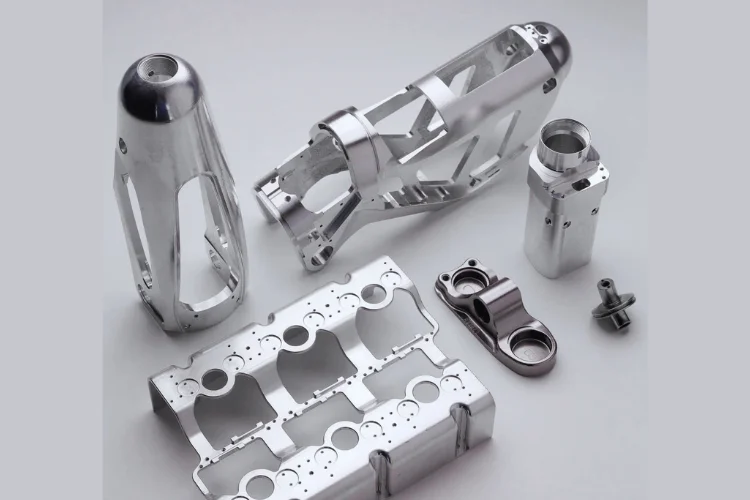

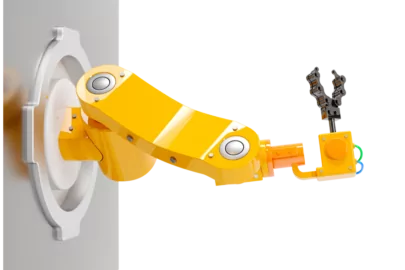

When a machinists receive the CAD (computer-aided design) model which is also called 3D file, they will start from programing tool paths based on the 3D file. A skilled machinist knows how to optimize the tool paths to lower CNC machining cost as well as to achieve tight tolerance. CNC machines can cut almost any material such as metal alloys, plastics, wood, stones, ceramics and more. Making custom machined parts needed for nearly every industry, including automotive, robotics, medical, aerospace, electronics and industrial. 3ERP provides CNC machining services and offers custom CNC quotes on various of materials ranging from commodity aluminum, steel, stainless steel, ABS, acetal to advanced titanium, Inconel, and engineered plastics like Teflon, PPS, PEI and PEEK. Learn more about CNC machining process

Services

Services